Soldering is a critical process in electronic manufacturing and semiconductor packaging, and one of the most common defects encountered is non-wetting solder. This issue occurs when the solder fails to form a proper bond with the base metal or pad, resulting in unreliable joints or open circuits. Understanding the mechanisms, causes, and solutions for non-wetting solder is essential for improving process stability and product reliability.

What Is Solder Wetting and Why Is It Important?

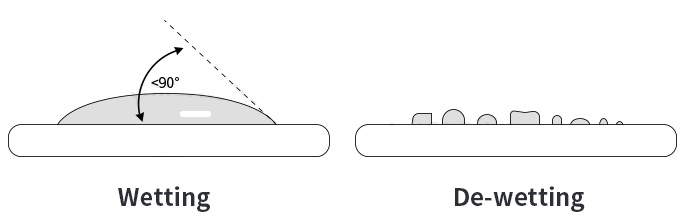

Solder wetting refers to the ability of molten solder to spread over and adhere to a surface, such as a component lead or a printed circuit board (PCB) pad. Proper solder wetting ensures a strong metallurgical bond and reliable electrical connection.

When solder wetting occurs effectively, a thin intermetallic layer forms between the solder and the substrate, providing both mechanical strength and electrical conductivity. Poor or non-existent solder wetting leads to weak joints, which may fail under thermal stress or vibration.

What Causes Non-Wetting Solder?

There are several factors that can lead to non-wetting solder, ranging from contamination to process design errors. The most common causes include:

- Oxidation of surfaces: Metal oxidation prevents solder from adhering properly. Copper, nickel, and tin are all susceptible to oxidation when exposed to air or moisture.

- Contaminants or residues: Oil, fingerprints, or leftover flux residues can act as barriers that prevent solder wetting.

- Insufficient flux activity: Flux removes oxides and improves solder wetting, but inadequate or low-activity flux cannot clean the surface effectively.

- Incorrect temperature profile: If the reflow or soldering temperature is too low, solder may not melt fully or fail to spread. Overheating, on the other hand, can damage flux and reintroduce oxidation.

- Poor wettable surface finish: Surface finishes like OSP (Organic Solderability Preservative), ENIG, or HASL can degrade over time and reduce solderability.

Extended storage or environmental exposure: Components stored for too long or in humid environments tend to oxidize, reducing their solder wetting capacity.

How Can Non-Wetting Solder Be Identified?

Non-wetting defects can be visually identified during inspection or post-solder testing. Common signs include:

- Solder that beads up instead of spreading smoothly.

- Dull, uneven, or patchy solder joints.

- Bare areas on the pad or lead surface after soldering.

- High electrical resistance or intermittent contact.

X-ray inspection or metallographic cross-sectioning can also help confirm poor solder wetting by showing incomplete intermetallic bonding between the solder and substrate.

How to Fix Non-Wetting Solder Problems?

To effectively fix non-wetting solder issues, manufacturers need to address both the root causes and process conditions. Below are several proven methods to improve solder wetting performance:

Clean the Surfaces Thoroughly

Ensure that both component leads and PCB pads are clean before soldering. Use isopropyl alcohol (IPA) or plasma cleaning to remove oil, oxidation, and organic residues.

Use High-Quality Flux

Select flux with strong activation suitable for the specific solder alloy and base material. Flux should remove oxides effectively without leaving excessive residue.

Optimize Temperature Profiles

Solder wetting relies heavily on proper heating. Use controlled temperature ramps to ensure solder reaches full melting while minimizing oxidation.

Use Vacuum or Inert Atmosphere Soldering

Solder wetting improves significantly under oxygen-free or vacuum environments. Vacuum reflow soldering, as developed by Chengliankaida Technology Co., Ltd, minimizes oxidation and voids, leading to better solder wetting and stronger joints.

Refresh or Replace Surface Finishes

If stored materials are old, re-tinning or applying a new finish such as ENIG or HASL can restore solderability.

Verify Solder Alloy Composition

Ensure the solder alloy meets manufacturing specifications. Alloys with impurities or low tin content can reduce wetting ability.

How Does Flux Chemistry Influence Solder Wetting?

Flux plays a crucial role in solder wetting by cleaning the surface and preventing reoxidation during soldering. There are three main types of flux:

- Rosin-based flux: Provides good cleaning but requires solvent cleaning afterward.

- Water-soluble flux: Strong cleaning performance, easily washable.

- No-clean flux: Convenient but has limited oxide removal ability.

Choosing the right flux depends on the substrate material, solder alloy, and process environment. Using an underpowered flux or not applying enough can easily cause non-wetting defects.

How Does Vacuum Soldering Improve Solder Wetting?

Vacuum soldering is one of the most effective solutions for non-wetting solder. The technology removes trapped gases and minimizes oxidation, creating an ideal environment for complete solder wetting.

Chengliankaida Technology Co., Ltd has developed advanced vacuum welding machines specifically designed for semiconductor packaging. By applying vacuum reflow technology, the solder joints achieve high density, low void rate, and superior reliability.

In vacuum conditions, molten solder spreads more uniformly, forming consistent intermetallic layers. This results in fewer voids and improved hermeticity — crucial for high-performance applications such as IGBT power modules and semiconductor devices.

How Can Process Control Prevent Future Non-Wetting Issues?

Long-term prevention depends on continuous process monitoring and strict quality control. Key practices include:

- Regular maintenance of equipment: Clean soldering tips, reflow chambers, and flux dispensers.

- Storage control: Keep components and solder materials in dry, temperature-controlled environments.

- Solderability testing: Periodically test materials using wetting balance or dip-and-look methods.

- Process optimization: Fine-tune temperature profiles, flux quantity, and conveyor speed for repeatability.

- Operator training: Ensure personnel understand the importance of surface preparation and soldering parameters.

What Are the Consequences of Ignoring Solder Wetting Problems?

Ignoring solder wetting problems can have serious consequences:

- Electrical failure: Non-wetted joints increase resistance or lead to open circuits.

- Thermal fatigue: Weak joints cannot withstand repeated heating cycles.

- Reduced product lifespan: Poor solder wetting accelerates degradation.

- High repair costs: Rework or replacement of defective boards increases production cost.

Proper control of solder wetting is therefore vital for long-term reliability and safety, especially in automotive electronics, aerospace, and semiconductor industries.

How Is the Future of Solder Wetting Improvement Shaping Up?

With continuous innovation in materials and process control, solder wetting technologies are advancing rapidly. Developments such as nano-coated surfaces, fluxless soldering, and AI-driven process monitoring are helping manufacturers reduce non-wetting defects even further.

Vacuum reflow and advanced soldering systems continue to play a crucial role in ensuring consistent wetting and reducing void rates. As technology progresses, manufacturers will increasingly rely on intelligent equipment and cleaner manufacturing environments to achieve defect-free solder joints.

Conclusion

Non-wetting solder remains a common challenge in modern manufacturing, but with the right approach, it can be effectively prevented and corrected. Understanding the principles of solder wetting, optimizing materials and processes, and adopting advanced methods like vacuum soldering all contribute to higher-quality connections and improved reliability.

By maintaining strict process discipline and embracing innovation, manufacturers can ensure stable solder wetting performance and deliver products that meet the highest standards of reliability and safety.

Comments