In the modern dairy industry, efficiency and hygiene are two of the most critical factors that determine the success of any production line. With increasing consumer demand for fresh, high-quality milk, dairy producers are constantly seeking innovative solutions to enhance their packaging processes. One such essential innovation is the milk bottler filler machine that has transformed how milk is processed, filled, and packaged for distribution. From small dairy farms to large-scale manufacturing facilities, this technology ensures precision, speed, and sanitation in every bottle filled.

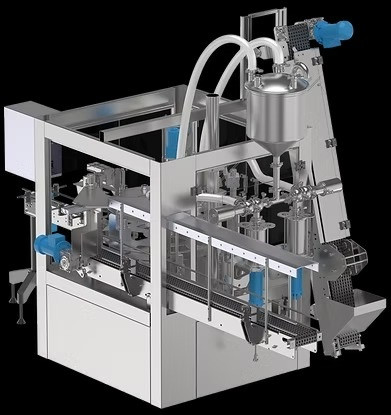

The milk bottler filler is a cornerstone of modern dairy automation. It’s designed to fill bottles with exact quantities of milk without spillage, wastage, or contamination. Unlike manual filling systems, which are prone to inconsistencies and hygiene risks, automated bottler fillers are built to handle large volumes of milk efficiently. These machines integrate advanced features like automatic cleaning systems, temperature control mechanisms, and high-speed filling heads to maintain the purity and freshness of the milk throughout the bottling process.

Different models of milk bottler fillers cater to diverse dairy production needs. Some are tailored for small-scale producers who need compact, semi-automatic systems, while others are fully automated and capable of handling thousands of bottles per hour. Depending on the plant’s setup, these machines can work with various bottle materials—glass, PET, or HDPE—and can accommodate different bottle sizes. The flexibility and scalability of these machines make them indispensable in today’s competitive dairy market.

In the middle of discussing automation and production efficiency, it’s important to highlight the core component—the milk bottler—which ensures accuracy, hygiene, and smooth operation in the filling line. The milk bottler is the heart of the entire packaging system. It controls the flow of milk from storage tanks into bottles, ensuring that each unit receives the exact quantity required. Modern bottlers are equipped with sensors and programmable logic controllers (PLCs) that monitor every stage of the filling process, preventing overflows and ensuring consistent output. By maintaining uniformity, these systems not only enhance the visual appeal of the final product but also reduce product loss and operational costs.

Hygiene remains one of the most significant concerns in dairy production, and milk bottler fillers are designed with this in mind. The machines are typically made from food-grade stainless steel, which resists corrosion and contamination. Many advanced models also include Clean-in-Place (CIP) systems that automatically sterilize internal components after each production cycle. This feature eliminates the need for manual cleaning, minimizing downtime and ensuring that every bottle of milk meets the highest safety standards. Additionally, airtight sealing systems and anti-foam technologies prevent milk oxidation and spoilage, keeping the product fresh from the factory to the consumer’s refrigerator.

Speed and efficiency are equally vital in the dairy industry, especially for companies operating in high-demand markets. Automated milk bottler fillers can handle multiple filling heads simultaneously, dramatically reducing production time. These machines are often integrated with capping and labeling systems, creating a seamless, end-to-end production line. This not only enhances productivity but also reduces the need for manual labor, allowing dairy producers to allocate human resources to quality control and logistics instead.

Beyond operational efficiency, modern milk bottler fillers contribute to sustainability goals. Many systems are designed to reduce water and energy consumption, aligning with global efforts to minimize environmental impact. Advanced models feature energy-efficient motors, precision sensors that limit waste, and recyclable materials in their construction. As dairy companies increasingly adopt eco-friendly practices, the role of sustainable filling technologies becomes even more vital in meeting environmental standards and consumer expectations.

Another important aspect of milk bottler filler technology is customization. Manufacturers can tailor these systems based on specific product requirements, such as low-fat milk, flavored milk, or plant-based alternatives. Some fillers are equipped to handle products with varying viscosities, allowing flexibility for diversified dairy product lines. This adaptability enables businesses to expand their offerings without overhauling their entire production system, making the investment in a milk bottler filler both practical and future-proof.

In conclusion, the milk bottler filler represents the perfect blend of innovation, hygiene, and productivity in the dairy industry. As consumer expectations evolve and the demand for high-quality milk continues to grow, the importance of precise and efficient filling systems becomes even more evident. The milk bottler not only ensures that every bottle is filled to perfection but also plays a crucial role in maintaining the integrity, freshness, and safety of the product. By investing in advanced bottling technology, dairy producers can optimize operations, reduce waste, and deliver superior-quality milk to consumers worldwide—setting new standards of excellence in modern dairy processing.

Comments