In welding, the tools you use, along with the safety equipment, determine the outcome and your safety. Welders have a ton of options today to protect themselves, as well as to make the job easier. Knowing the right tools to use, from consumables to safety products, is going to be the difference in your shop.

The Importance of Quality Consumable

Every welder knows “the wire makes the weld” and there is truth to this statement, in that the type of wire you use dictates the finish and strength of a weld. For example, the convenience of Gasless MIG Wire is hard to beat, particularly when your working outdoors and shielding gas presents a problem. You certainly can’t beat the clean, strong welds produced (sometimes better), by wire with no added shielding gas, or take into consideration the ease of use on your workflow, jobs where you might use the gasless rod to finish a piece of work that you started with a standard rod, or any occasion you want to be versatile and get away from the gas setup.

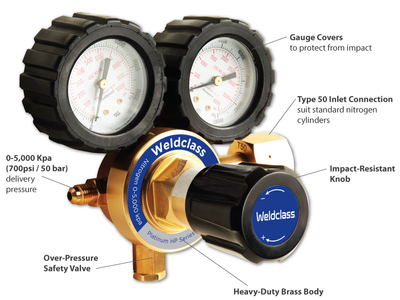

Precision in Gas Flow Control

Welding gases need to be safely regulated for consistent performance. Hence, we have a regulator for Nitrogen Gas. By precisely regulating pressure or flow, a nitrogen gas regulator ensures safety and accuracy for the welds you are backing up. A good quality gas regulator will be a worthy investment in time, efficiency, and lowering the chances of doing rework for poor welds.

Protecting Your Health While Welding

While welding safety does mean gloves and jacket, it also involves exposure to dangerous fumes or flying debris. This is why some professionals are happy about Respirator Welding Helmets. A respirator welding helmet has a standard face shield coupled with respiratory protection so that while the user welds, fresh air is being consumed while being fully protected from high heat from projectiles of radiation.

Advanced Helmet Options

Face shields are no longer the only option available for your safety. A Welding Helmet With Respirator takes safety to another level by integrating the filtration systems right into the helmet. Doing so eliminates the need for separate products while providing convenience and nasty particulates or fumes protection.

Shielding Your Surroundings

Welding is not only a safety consideration for yourself; it is also a safety concern for your surroundings. A welding blanket protects the surroundings by serving as a barrier between sparks or molten metal and any equipment or surface that could be damaged. When safety and cleanliness are at stake, a welding blanket is a very important consideration.

Reducing Harmful Fumes

Modern shops are increasingly aware of air quality. Welding fume extractors remove and reduce welding smoke from the breathing space; this meets safety standards and ensures a well-being work environment.

Choosing the Right Welding Helmet

This is one safety accessory that you can see is necessary for use. Besides giving eye and face protection against rays emitted from the arc, modern welding helmets are developed for comfort and clarity, with some special features like auto-darkening lenses that help in safety and increase productivity by reducing eye fatigue so that welders can focus on their welding.

Conclusion

Welding accessories are for productivity, safety, and comfort; even the longevity of an individual is strongly ensured. Consumables like Gasless MIG Wire do their bit, while protective gear like welding helmets, blankets and fume extractors all work to enhance your performance and assure your well-being in both long and short terms. By simply choosing good quality products, your weld will be safe, accurate, and efficient wherever you may be working or in the shop.

Comments