Surgical precision demands the right tools, and few instruments exemplify this principle better than Duval forceps. These specialized surgical instruments have become indispensable in operating rooms worldwide, serving as trusted companions for surgeons who require reliable, versatile tools for delicate procedures. Understanding the unique characteristics and applications of Duval forceps helps medical professionals make informed decisions about their surgical instrument needs. Azeemed Instruments® is dedicated to providing high-quality surgical tools that meet the needs of professionals, ensuring that every surgeon has access to the precision instruments they require for optimal patient outcomes.

Understanding Duval Forceps Design and Construction

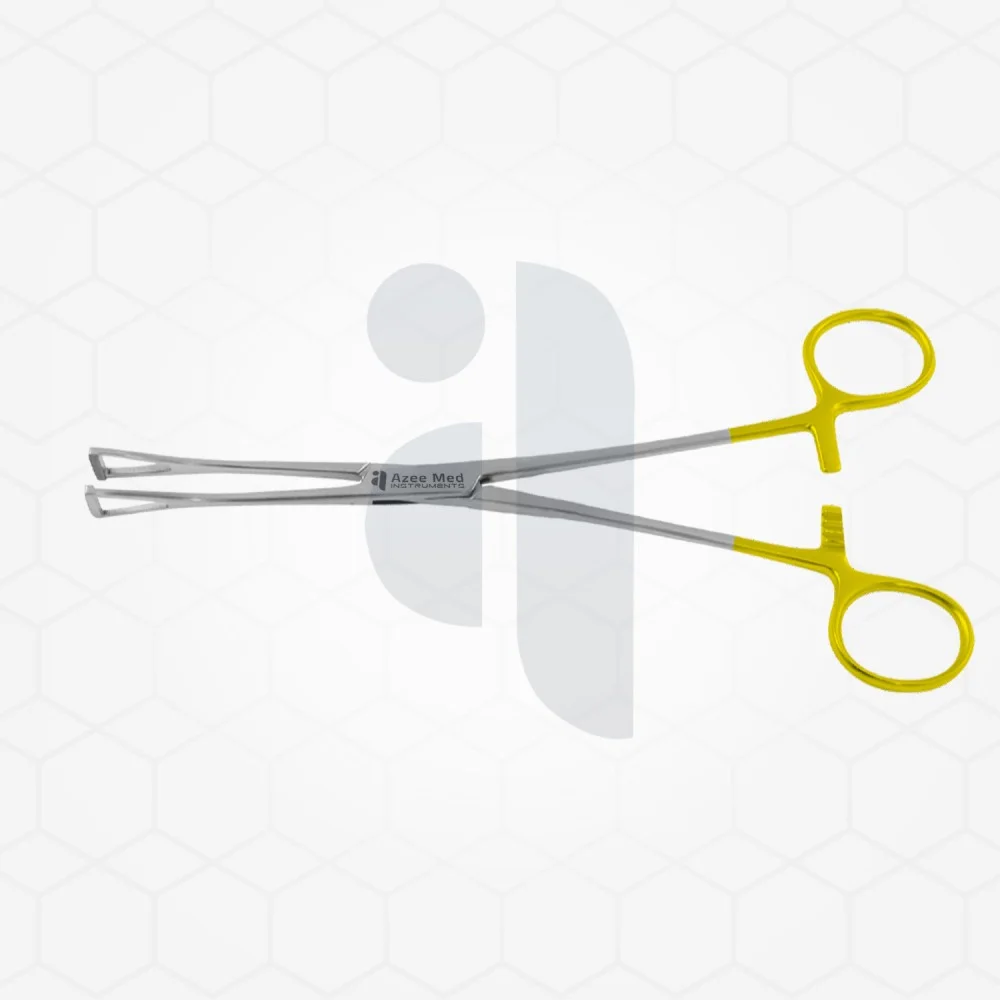

The distinctive design of Duval forceps sets them apart from other surgical instruments. These forceps feature curved or angled jaws that provide enhanced visualization and access to confined surgical spaces. The precision-engineered tips are designed with specific serrations or teeth patterns that ensure secure tissue grasping without causing excessive trauma.

The construction of quality Duval forceps relies on premium-grade stainless steel, which offers exceptional durability and corrosion resistance. This material choice is crucial for instruments that must withstand repeated sterilization cycles while maintaining their mechanical integrity. The ergonomic handle design reduces hand fatigue during extended procedures, allowing surgeons to maintain precise control throughout complex operations.

Manufacturing processes for these instruments involve multiple quality control checkpoints to ensure consistent performance. Each forceps undergoes rigorous testing for jaw alignment, spring tension, and overall functionality before reaching operating rooms.

Primary Applications in Surgical Procedures

Duval forceps excel in numerous surgical specialties, with their versatility making them valuable across multiple medical disciplines. In general surgery, these instruments facilitate tissue manipulation during abdominal procedures, allowing surgeons to grasp and position organs with minimal tissue damage.

Cardiovascular surgeons rely on Duval forceps for delicate procedures involving blood vessels and cardiac tissue. The precision grip and controlled pressure distribution help prevent inadvertent punctures or tears in sensitive vascular structures. The curved design particularly benefits procedures requiring access to posterior cardiac surfaces.

Plastic and reconstructive surgeons frequently use Duval forceps during tissue flap procedures and microsurgical applications. The fine tips enable precise handling of delicate tissues while maintaining adequate holding strength. This balance between gentleness and security proves essential in procedures where tissue viability is paramount.

Neurosurgical applications benefit from the controlled grip that Duval forceps provide when handling neural tissues. The ability to grasp without excessive compression helps protect delicate nerve structures during tumor removal or vascular procedures.

Key Advantages and Benefits

The curved design of Duval forceps offers significant advantages over straight forceps in many surgical situations. This curvature allows surgeons to work around anatomical structures while maintaining clear visualization of the operative field. The enhanced access reduces the need for additional retraction, potentially minimizing tissue trauma.

Superior grip control represents another major benefit of well-designed Duval forceps. The balanced jaw pressure ensures secure tissue handling without the crushing effects that can occur with less sophisticated instruments. This controlled grip proves particularly valuable when working with fragile tissues or when precise positioning is required.

The self-retaining feature of some Duval forceps variants allows surgeons to maintain tissue position without continuous manual pressure. This capability frees up the surgeon's hands for other tasks while ensuring consistent tissue presentation throughout the procedure.

Durability and longevity make Duval forceps an excellent investment for surgical facilities. Quality instruments maintain their precision and functionality through thousands of use cycles, providing consistent performance that surgeons can rely upon.

Material Quality and Manufacturing Standards

The selection of appropriate materials is crucial for Duval forceps performance and longevity. High-grade stainless steel alloys provide the necessary strength, flexibility, and corrosion resistance required for surgical applications. These materials must meet stringent medical device standards to ensure biocompatibility and safety.

Surface finishing techniques play a vital role in instrument functionality. Properly finished surfaces resist bacterial adhesion and facilitate thorough cleaning and sterilization. The smooth finish also reduces the risk of tissue snagging or tearing during use.

Heat treatment processes during manufacturing ensure optimal spring characteristics and jaw alignment. These thermal processes must be carefully controlled to achieve the proper balance between strength and flexibility that makes Duval forceps effective surgical tools.

Quality assurance protocols verify that each instrument meets established specifications for dimensions, functionality, and performance. These rigorous testing procedures help ensure consistent quality across production batches.

Maintenance and Sterilization Considerations

Proper maintenance of Duval forceps is essential for preserving their functionality and extending their service life. Regular inspection for wear, corrosion, or damage helps identify instruments that require repair or replacement before they compromise surgical outcomes.

Cleaning protocols must address the unique design features of Duval forceps, including the curved jaws and articulation points where debris might accumulate. Ultrasonic cleaning systems effectively remove contaminants from hard-to-reach areas while preserving the instrument's precision surfaces.

Sterilization procedures must be compatible with the materials and construction of Duval forceps. Steam sterilization remains the most common method, though proper packaging and loading techniques are essential to prevent damage during the sterilization cycle.

Storage systems should protect the delicate tips and maintain proper jaw alignment. Specialized instrument trays and protective covers help prevent damage during storage and transport.

Selection Criteria for Surgical Facilities

Choosing appropriate Duval forceps requires consideration of several factors, including the specific surgical procedures performed, surgeon preferences, and facility requirements. The size and curvature of the forceps should match the intended applications and anatomical access requirements.

Handle design preferences vary among surgeons, with some favoring traditional finger rings while others prefer thumb-operated mechanisms. The choice often depends on the surgeon's hand size, preferred grip style, and the specific demands of their surgical specialty.

Quality certifications and regulatory compliance ensure that selected instruments meet necessary safety and performance standards. Facilities should verify that their instruments carry appropriate FDA clearances or CE markings as required by their regulatory environment.

Supplier reputation and support services can significantly impact the long-term value of instrument purchases. Reliable suppliers provide consistent quality, responsive customer service, and comprehensive warranty coverage.

Innovations in Duval Forceps Design

Modern manufacturing techniques have enabled several innovations in Duval forceps design. Advanced metallurgy has produced alloys with improved fatigue resistance and enhanced spring characteristics. These materials maintain their performance characteristics through extended use cycles.

Ergonomic improvements have focused on reducing surgeon fatigue and improving control precision. Modified handle geometries and surface textures provide enhanced grip security while reducing the force required for operation.

Specialized tip configurations have been developed for specific surgical applications. These variations include different serration patterns, jaw shapes, and closing mechanisms optimized for particular tissue types or procedural requirements.

Integration with surgical navigation and robotic systems has led to modified designs that accommodate technological enhancements while maintaining the fundamental advantages of traditional Duval forceps.

Quality Assurance and Brand Excellence

Azeemed Instruments® exemplifies the commitment to quality that surgical professionals require from their instrument suppliers. The dedication to providing high-quality surgical tools reflects an understanding that surgical outcomes depend on reliable, precise instruments that perform consistently under demanding conditions.

Quality control processes ensure that every Duval forceps meets exacting standards for dimensional accuracy, functional performance, and material integrity. These rigorous standards help maintain the reputation for excellence that characterizes premium surgical instruments.

Continuous improvement initiatives incorporate feedback from surgical professionals to enhance instrument design and performance. This collaborative approach ensures that instruments evolve to meet changing surgical needs and techniques.

Comprehensive testing protocols verify that instruments maintain their specifications throughout their service life, providing surgeons with the confidence they need to focus on patient care rather than instrument reliability.

The selection of Duval forceps represents an investment in surgical precision and patient outcomes. Understanding the unique characteristics, applications, and quality considerations of these essential instruments helps medical professionals make informed decisions that support their commitment to excellent patient care. Quality manufacturers like Azeemed Instruments® continue to advance the standards of surgical instrumentation, ensuring that surgeons have access to the tools they need for successful procedures.

Comments