In modern production setups, specialized machinery plays a crucial role in shaping products with accuracy and speed. Punjab, especially Ludhiana, has emerged as a hub where industries continuously evolve with advanced technologies to meet the demands of both domestic and global markets. The use of high-performance machines not only ensures product consistency but also drives economic growth by supporting large-scale production. This article explores the significance of specialized machinery in Punjab while highlighting notable solutions and suppliers shaping the industry.

The Role of Advanced Cold Forging Machines

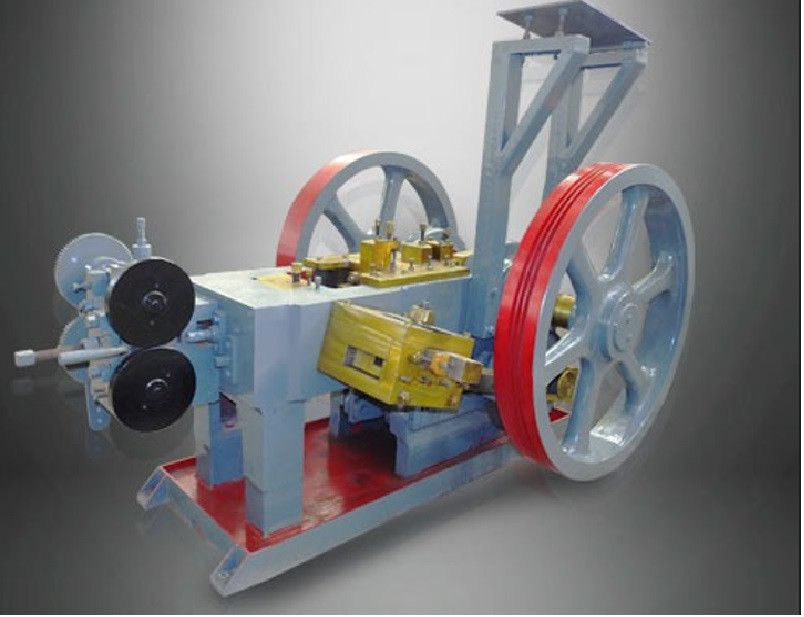

Cold forging is a process widely appreciated for its ability to produce strong and durable components. A Cold Forge Header Machine in Ludhiana is an excellent example of how advanced equipment transforms production. By reshaping metals at room temperature without compromising their strength, these machines create highly precise parts used across various industries including automotive, construction, and hardware manufacturing.

Manufacturers in Ludhiana have adopted this technology to meet increasing demand for parts that require uniformity and resilience. A Cold Forge Header Machine in Ludhiana is particularly valued because it reduces material wastage, lowers production costs, and increases efficiency. This has made Ludhiana a preferred location for businesses seeking reliable forging solutions.

Importance of Trimming Machines in Manufacturing

Trimming machines hold equal importance in the industrial process as they help in shaping and finishing products after forging or molding. A Trimming Machine Manufacturer in Punjab plays a vital role in providing high-quality machines that ensure the final product meets exact design specifications. These machines eliminate excess material and give the product a polished finish suitable for use or further assembly.

Industries in Punjab rely heavily on trimming machines to maintain accuracy in mass production. The availability of reliable manufacturers ensures that businesses can continuously improve their product quality while keeping operations smooth. A Trimming Machine Manufacturer in Punjab not only supports local industries but also contributes to making Punjab a trusted hub for industrial machinery.

Thread Rolling Machines and Their Growing Relevance

Thread rolling is another critical process in the manufacturing world. Unlike cutting methods, thread rolling enhances the strength of the material while creating uniform threads. This process has gained popularity due to its ability to produce high-quality fasteners and threaded components efficiently.

A Thread Rolling Machine Supplier in India provides essential support to industries by offering machines that can handle diverse requirements. With growing demand for fasteners in sectors such as automotive, aerospace, and construction, reliable suppliers ensure uninterrupted availability of advanced thread rolling technology. A Thread Rolling Machine Supplier in India not only serves the domestic market but also contributes to global exports, strengthening India’s position in manufacturing.

Specialized Solutions by Samrat Machines

Among the trusted names in the machinery sector, Samrat has built a reputation for delivering innovative and durable machines. A Samrat Header Machine in Punjab is a notable example of how the region continues to produce world-class solutions for industrial needs. These machines are specifically designed to meet the requirements of large-scale production while ensuring accuracy in every unit manufactured.

The reliability and performance of a Samrat Header Machine in Punjab make it a preferred choice for industries aiming to balance quality with efficiency. By adopting such advanced equipment, manufacturers in Punjab maintain their competitive edge in both local and international markets.

Conclusion: A Future Built on Precision Machinery

The growth of Punjab as an industrial hub is closely tied to the availability of advanced machinery that enhances production capabilities. From forging to trimming, and from threading to specialized header machines, every stage of the manufacturing process is strengthened by modern equipment. Reliable suppliers and manufacturers ensure that businesses achieve consistency and efficiency in their operations.

For industries seeking technology-driven growth, solutions such as cold forge headers, trimming machines, and thread rolling systems remain essential. Companies like Kalsi IT Solutions further bridge the gap between businesses and advanced machinery providers through innovative digital support and industrial services.

Comments