Punjab, particularly the industrial hub of Ludhiana, stands as a formidable nucleus in India's precision engineering landscape, driving innovation in the manufacturing of Cold Forging Machines and associated equipment. This region has cultivated a deep-rooted expertise, Cold Forging Machine Manufacturer in Punjab supplying critical machinery that forms the backbone of the fastener and hardware industries both domestically and internationally.

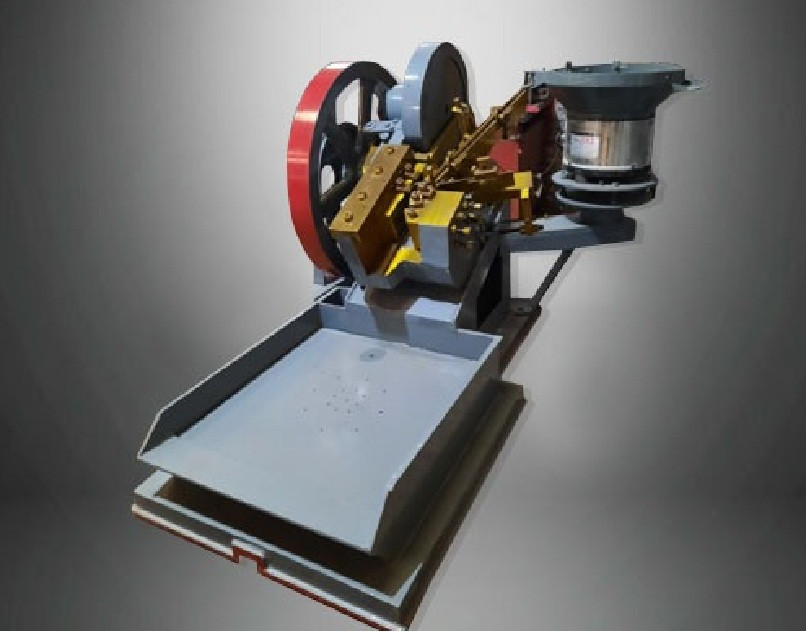

The demand for high-strength, dimensionally accurate components has positioned Cold Forging as a superior manufacturing process. Unlike hot forging, this method works the metal below its recrystallization temperature, enhancing material properties like tensile strength and yield strength while offering exceptional surface finish and material savings. At the heart of this process lies the Cold Forge Header Machine in Ludhiana, a specialized piece of equipment designed for the high-speed production of bolts, screws, and rivets. Manufacturers in Ludhiana have honed the design and construction of these machines, focusing on robust frames, precise tooling, and high-speed operation to meet the rigorous demands of mass production.

Among the key players, the name Samrat Header Machine in Punjab often cited in the context of quality and reliability in Punjab. Companies bearing this reputation specialize in manufacturing multi-station cold headers, catering to diverse industry needs from automotive to construction. Their commitment to utilizing high-grade materials and incorporating advanced automation and safety features ensures that their machines deliver consistent performance and a long operational lifespan. This regional specialization has cemented Ludhiana's reputation as a go-to source for heavy-duty, reliable forging equipment.

The production journey of a fastener is often completed by Thread Rolling Machines, another crucial piece of equipment where suppliers in India, many originating from or linked to Punjab's ecosystem, excel. Thread rolling is a chipless process that forms threads by rolling a blank between hardened dies. This process, also a form of cold working, not only creates accurate threads but also improves their strength by orienting the material's grain structure along the thread contours. A Thread Rolling Machine Supplier in India is a vital link, providing the final layer of sophistication to the fastener manufacturing line. The focus here is on precision, speed, and the capability to handle a wide range of thread sizes and profiles, from fine metric threads to coarse industrial ones.

The success of Cold Forging Machine Manufacturers in Punjab is a testament to the state's industrious nature and its engineering prowess. They are not merely assembling components; they are designing complex, heavy-duty machinery that operates under extreme pressure and stress. By integrating advanced hydraulics, pneumatics, and control systems, these manufacturers ensure their machines offer superior productivity and minimal downtime. This localized expertise creates a complete ecosystem, where manufacturers of forging headers and suppliers of thread rolling machines collaborate, ensuring a seamless technology transfer and maintenance support for the entire fastener production line. In essence, Punjab provides the muscle and the precision that is driving the modern industrial landscape.

Comments