In today’s industrial world, innovation in materials and chemical solutions plays a vital role in achieving sustainability, durability, and visual excellence. Among these advancements, Solvent Dye, Liquid Solvent Dyes, and Flame Retardants—especially Halogen Free variants—have become indispensable across multiple industries, including plastics, textiles, coatings, and polymers. Their unique properties not only enhance aesthetic appeal but also improve safety and environmental performance.

Solvent Dyes are highly versatile colorants known for their superior solubility in organic solvents, oils, waxes, and plastics. They are non-polar and dissolve easily in materials like PVC, acrylics, and polystyrene, ensuring vibrant and uniform coloration. Unlike pigments, solvent dyes do not form particles in the material but blend homogeneously, providing excellent transparency and brilliance. This makes them the preferred choice for applications such as automotive interiors, packaging materials, inks, and cosmetic products. Liquid Solvent Dye /s offer an even greater advantage in modern manufacturing by simplifying blending and dispersion processes. Their liquid form ensures easy handling, precise dosing, and consistent color strength, reducing waste and enhancing production efficiency. Industries dealing with plastics and coatings rely heavily on these dyes for their exceptional light fastness, thermal stability, and compatibility with diverse polymer systems.

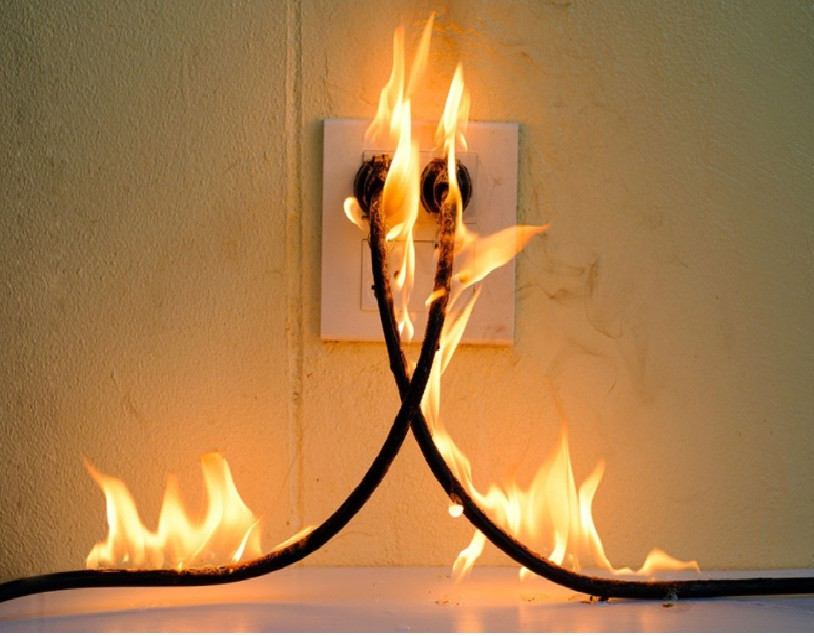

Beyond aesthetics, safety and sustainability have become critical considerations in material design. This is where Flame Retardants play an essential role. They are chemical compounds that inhibit or resist the spread of fire, making materials safer to use in environments with high fire risk. Traditional flame retardants often contained halogens such as chlorine or bromine, which, although effective, posed environmental and health concerns due to the release of toxic gases during combustion. In response, the industry has shifted towards Halogen Free Flame Retardants, which provide equally effective fire resistance without compromising air quality or ecological balance.

Halogen Free flame retardants are composed of elements like phosphorus, nitrogen, and mineral compounds that act by creating a protective char layer or releasing water to cool the burning surface. They are widely used in electrical appliances, construction materials, automotive parts, and textiles, offering superior thermal stability and low smoke emission. Their adoption not only aligns with global environmental regulations such as RoHS and REACH but also supports companies’ sustainability goals.

The synergy between Solvent Dyes, Liquid Solvent Dyes, and Halogen Free Flame Retardants offers a powerful combination of beauty, performance, and safety. For instance, manufacturers of colored engineering plastics can achieve deep, vivid hues while maintaining flame resistance and compliance with eco-friendly standards. This balance between aesthetics and functionality is crucial for industries striving for innovation without compromising responsibility.

As technology advances, the development of next-generation solvent dyes and halogen-free solutions continues to expand. They represent the future of material science—where vibrant color meets enhanced safety and environmental consciousness. Whether in high-performance plastics, coatings, or consumer goods, these chemical innovations redefine the standards of modern manufacturing by ensuring that every product looks exceptional, performs reliably, and protects both people and the planet.

Comments